Cleaners

Danagri-3S offer the full SKIOLD range of grain and seed cleaners for either milling operations, Intakes or fine cleaning. There is a machine to farm businesses up to commercial grain and seed handling operations.

Most cleaners have double screens to enable removal of both large items like sticks and stones and also a fine screen to remove sand and grits that reduce the lifetime of mill components.

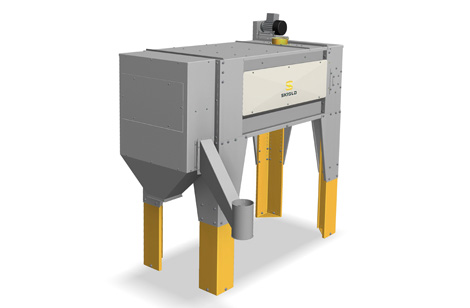

SKIOLD Twin Drum Cleaner

- Sealed design with minimal dust emissions

- Efficient cleaning with two screens

- Cleaning capacity of up to 3200kg/hr

- Easy connection to SKIOLD Mills

- Multiple screen choices

- Adjustable height

- Includes brush to keep main screen clean

SKIOLD Screen Cleaner

X

SKIOLD Screen CleanerShow Full Screen

SKIOLD Screen CleanerShow Full Screen SKIOLD cleaner in a milling systemShow Full Screen

SKIOLD cleaner in a milling systemShow Full Screen SKIOLD cleaner on mezzanine floor above a Disc MillShow Full Screen

SKIOLD cleaner on mezzanine floor above a Disc MillShow Full Screen

- Sealed design with minimal dust emissions

- Oscillating cleaning with two screens

- Cleaning capacity of up to 6000kg/hr

- Easy connection to SKIOLD Mills

- Multiple screen choices

- Adjustable height

- Effective cleaning of screens with rubber balls

SKIOLD DAMAS Uniseed & Duoseed Screen Cleaners

- Larger capacity machines for large farm & commercial operations

- Sealed design with minimal dust emissions

- Oscillating cleaning 2x screens on Uniseed,

- 4x screens on Duoseed model

- Can be used for Pre-cleaning or fine cleaning

- Cleaning capacity of up to 60 tph

- Multiple screen choices