Bale Shredders and Bale Breakers

SBB1800 Twin shredder, 3-16T p/hrShow Full Screen

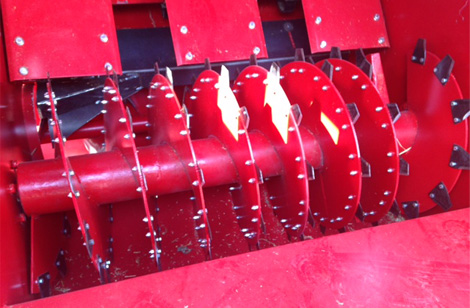

SBB1800 Twin shredder, 3-16T p/hrShow Full Screen Shredder rotor on SBB1400Show Full Screen

Shredder rotor on SBB1400Show Full Screen SBB1400 shredder with bale opener, mill, filter & augerShow Full Screen

SBB1400 shredder with bale opener, mill, filter & augerShow Full Screen SBB1800 with twin augers & hammer millShow Full Screen

SBB1800 with twin augers & hammer millShow Full Screen MTX mixer shredderShow Full Screen

MTX mixer shredderShow Full Screen SBB1800 with twin auger dischargeShow Full Screen

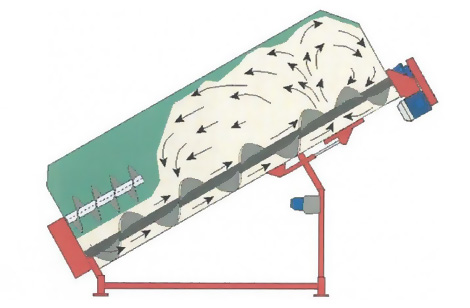

SBB1800 with twin auger dischargeShow Full Screen Diagram of straw flow in MTX mixer shredderShow Full Screen

Diagram of straw flow in MTX mixer shredderShow Full Screen

The SBB1400 and 1800 bale shredders are the current market leaders for mass production of straw products. With single and twin shredder rotors available, all of which are direct drive with Zone 22 gear driven motors. The power of direct drive motors, the spring-loaded shear bars, sonar sensors and new SBO work together to maintain a fluid flow of product to the mill…

The smaller SBB1400 comes with the option of a 5.5 or a 7.5kW motor to drive its single shredder rotor, with the SBB1800 ranging from 7.5 to 11 kW to drive its twin shredders.

For those customers who require a mixture of material we also offer our range of MTX-H Mixer shredders. These machines combine the processing power of the SBB range with the ability to add various ingredients to the mix such as differing varieties of straw, wood shavings, additives etc. The MTX-H machines vary greatly is size from 18 m3 to 50 m3.

Across the range of Cormall straw processors we offer machines which can process capacities up to 25 tones per hour on a single machine dependant on final length requirement.